Reliable technology for electric flight

By supplying the drive system, we solve one of the biggest challenges in complex and long-term product development in aviation for our B2B customers.

With 600,000 operational hours and 160,000 flight hours, Lange Aviation is globally #1 in electric flight.

Our unique expertise in certification and many years of series production of electric aircraft, energy storage systems and energy generators support the development of new electric aircraft and the transformation of existing combustion powered models.

Better planning security, concentration on the essentials, shorter development cycles, high reliability and precision – these are the most important reasons for our B2B customers to work with Lange Aviation.

We fully support the UN Charter for Carbon Footprint Reduction and national calls for “Green Tech” in the air.

The use of highly scalable subassemblies “made in Germany by Lange Aviation” makes it easier for engineers to make high-end electrically powered products ready for market. To this end, we operate our own research & development as well as production facilities in Zweibrücken (Germany).

Our B2B products

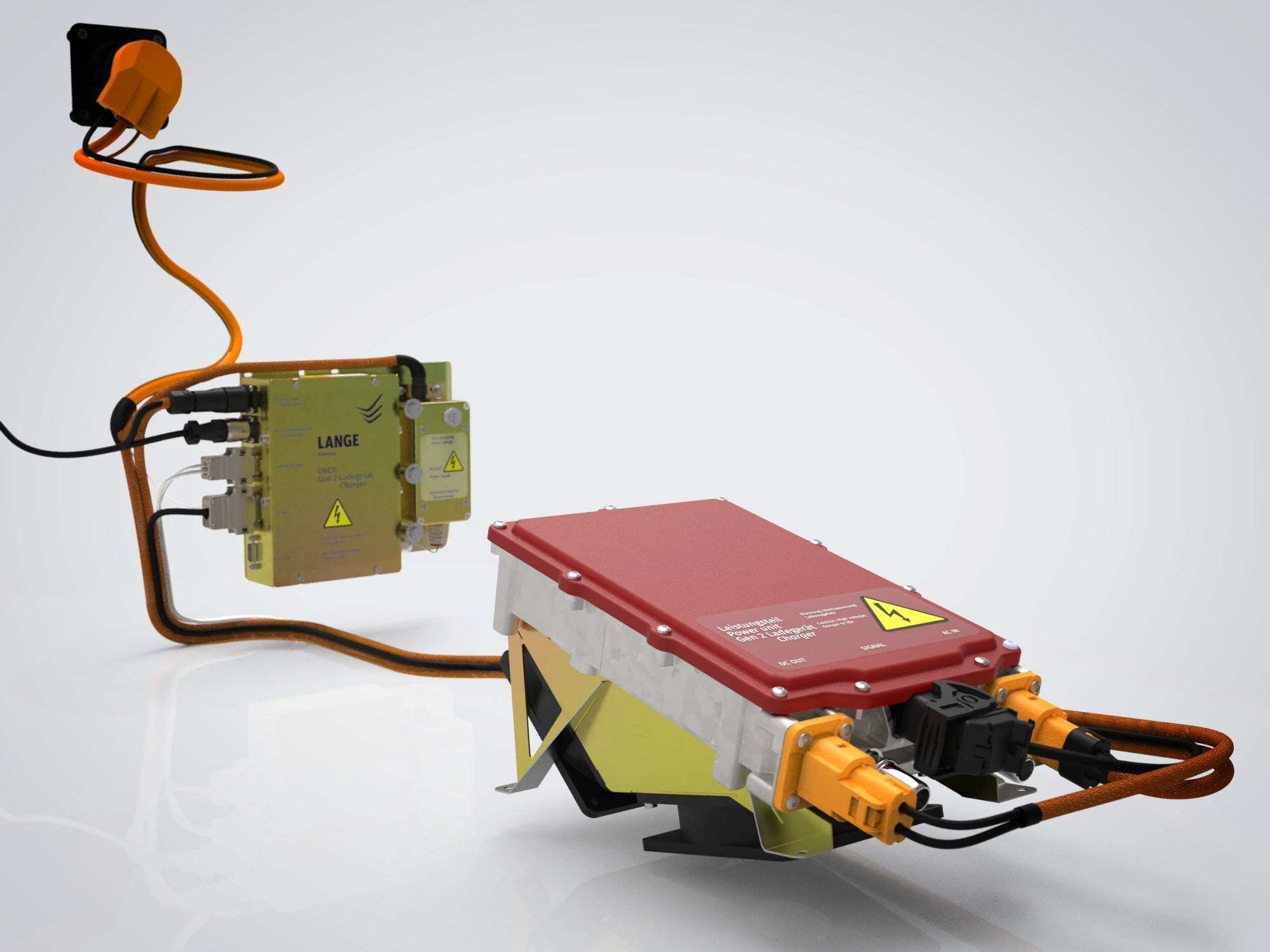

Power Electronics

DAL C

Battery system

DAL C

Charging system

DAL C

Electric Drive Control System

DAL D

Application scenarios

Technology from Lange Aviation is suitable for 1- to 19-seat electric aircraft of classic design with fixed wings, novel tilt-wing concepts and for most eVTOLs.

We supply complete powertrains, energy storage and power generation solutions, as well as control components and software. In addition, we provide know-how on integration and system customization.

Our offer is aimed at B2B customers.

Certifications

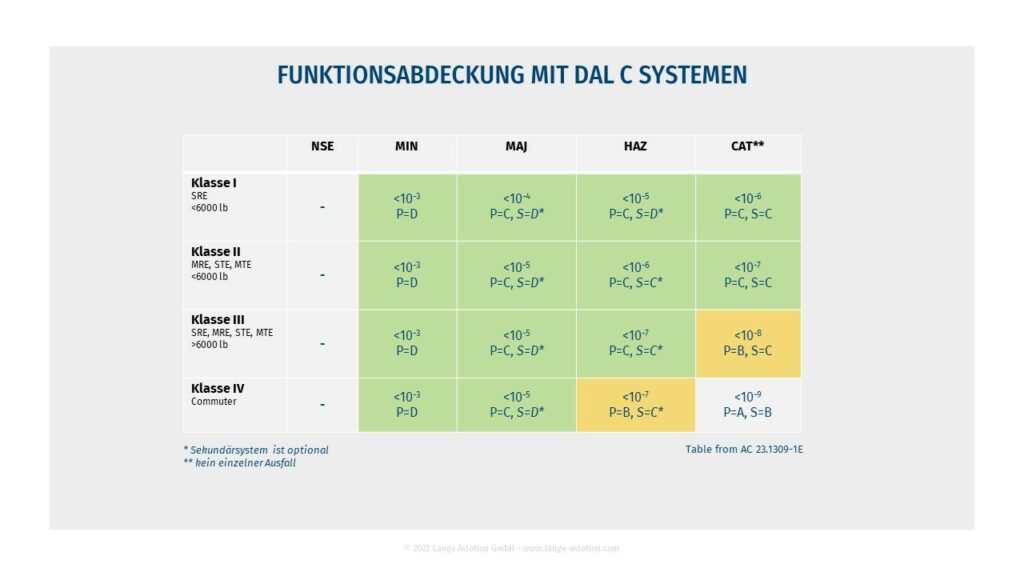

With our DAL C systems, our customers cover a wide range of applications (see diagram).

We work with the following standards:

- Compliant with ED-79 / ARP 4754A

- Functional risk assessment and safety evaluation (FTA, FMEA) according to ARP 4761

- Development processes according to DO-178C and DO-254

- Indoor environmental tests according to DO-160: shock, altitude, temperature.

- Certification basis CS-23, CS-22, CS-E

Architecture

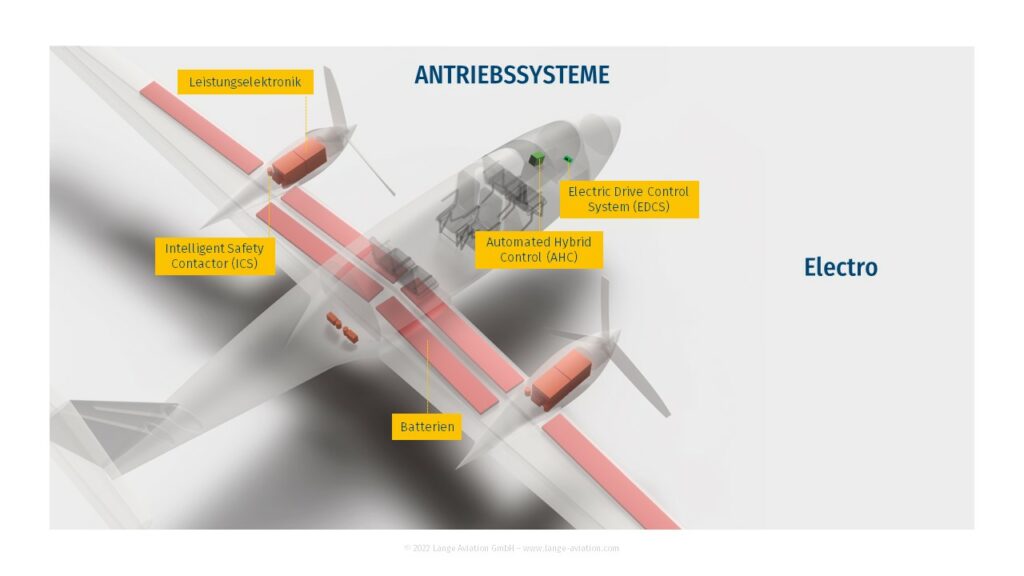

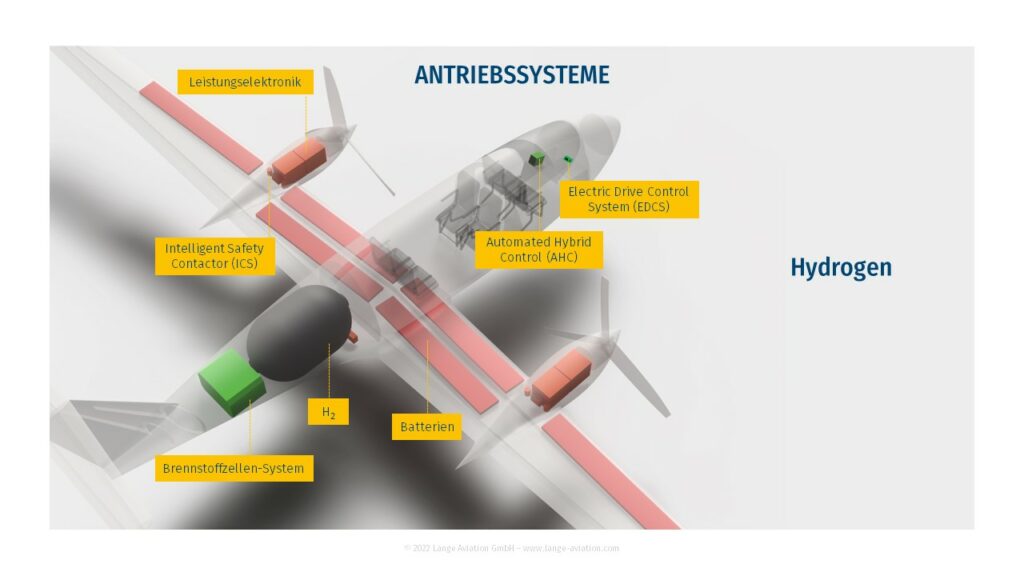

Lange Aviation supplies complete systems and harmonized individual subassemblies for the electrification of aircraft propulsion systems.

By separating power and control modules, we can tailor standardized products to individual requirements.

Our customers can choose between battery-only solutions and hybrid systems with fuel cells.

Performance data

Our range of systems connects – with multiple redundancies:

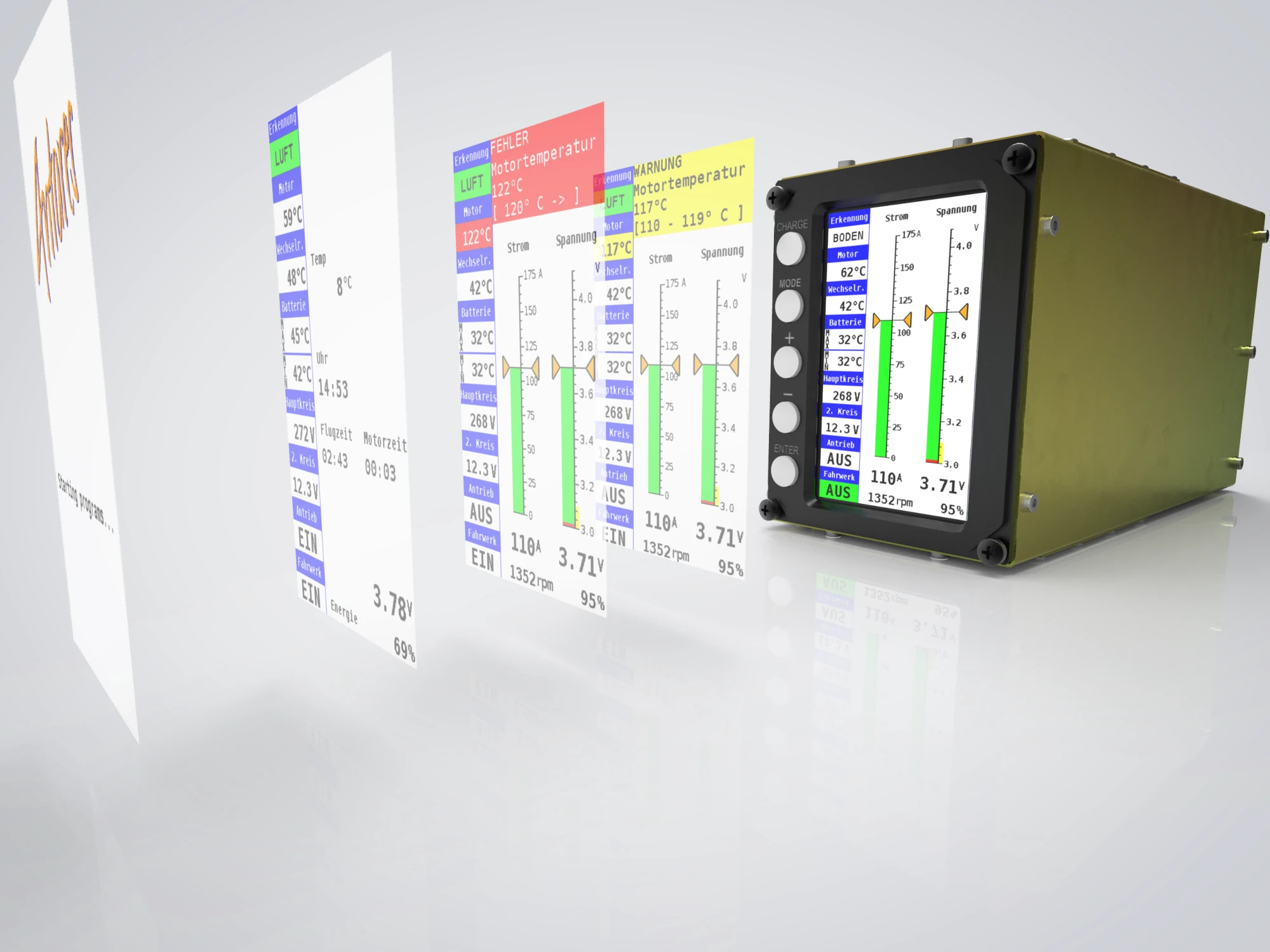

- Human/computer/machine interface in the cockpit

- Power electronics for controlling motors up to 400 VDC / 800 VDC

- sophisticated power management for power extraction from batteries or fuel cells

- On-board or external charger

- Monitoring of performance and system health

- Battery systems – based on our experience and expertise, we ensure that the right battery cells are selected from those available on the market.

Have a look at our presentation onto the right: “Certified electric propulsive components”, May 2022

References

We would be happy to present selected customer scenarios to you in a personal dialog. You can find out more about our technology partners here.

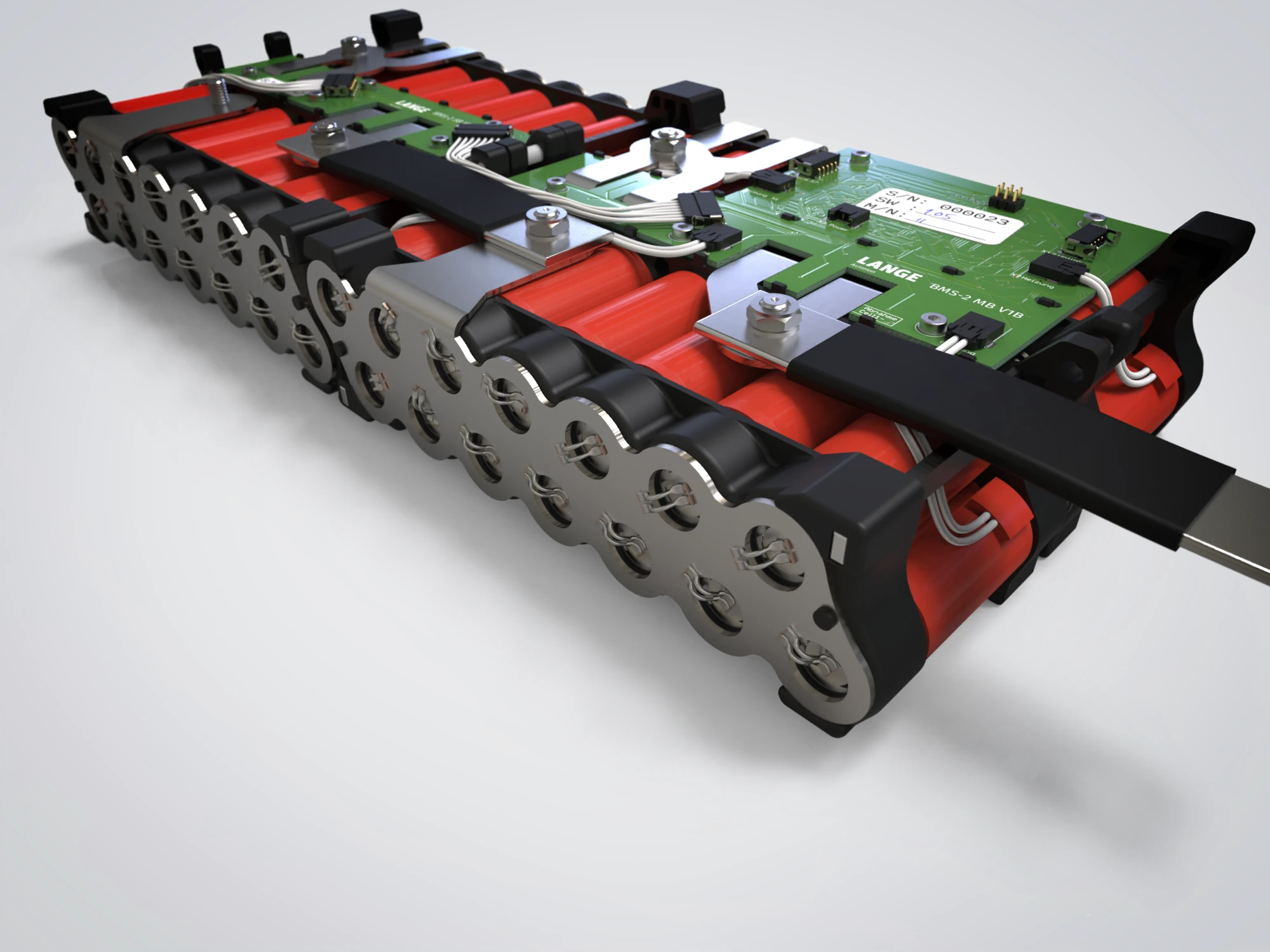

Antares.RED.3 Battery system

RED represents “Reliable Electric Design”. A sophisticated and robust battery management system (BMS) facilitates higher flights and longer ranges than ever before. RED.3 is the third generation of our battery systems and it is based on the 21700 cell format. Since 1996, we have been developing battery systems that can be fully integrated into the structure of aircraft, yet are extremely easily accessible and can be upgraded by fitting more modern cells.. This makes our battery systems sustainable and future-oriented. Our “Protect.ahead” safety concept ensures that thermal runaways occur extremely rarely and then have virtually no consequences. A redundant battery management system guarantees maximum reliability. An integrated logger system stores battery data over the life of the battery and allows effective monitoring of the battery system. Chargers that can be integrated into the aircraft increase mobility. Control, monitoring and updates “over the air” increase user comfort and simplify maintenance.

We make it fit.

Each aircraft project is individual. The architecture of our subassemblies allows flexible adaptation to customer requirements. Should there be any discrepancies between your designs and our product range, our R&D team can help.

For this purpose, we offer the following services, depending on availability and in individual consultation. Please contact us for more details.

System customization

Workshops and consulting- as well as engineering-services for evaluation, customization, re-certification and production planning.

Individualized development

R&D projects for custom design of new components and systems on behalf of customers, production planning and certification (if required).

Prototypes

Using state-of-the-art technologies, we develop individual items according to your design.

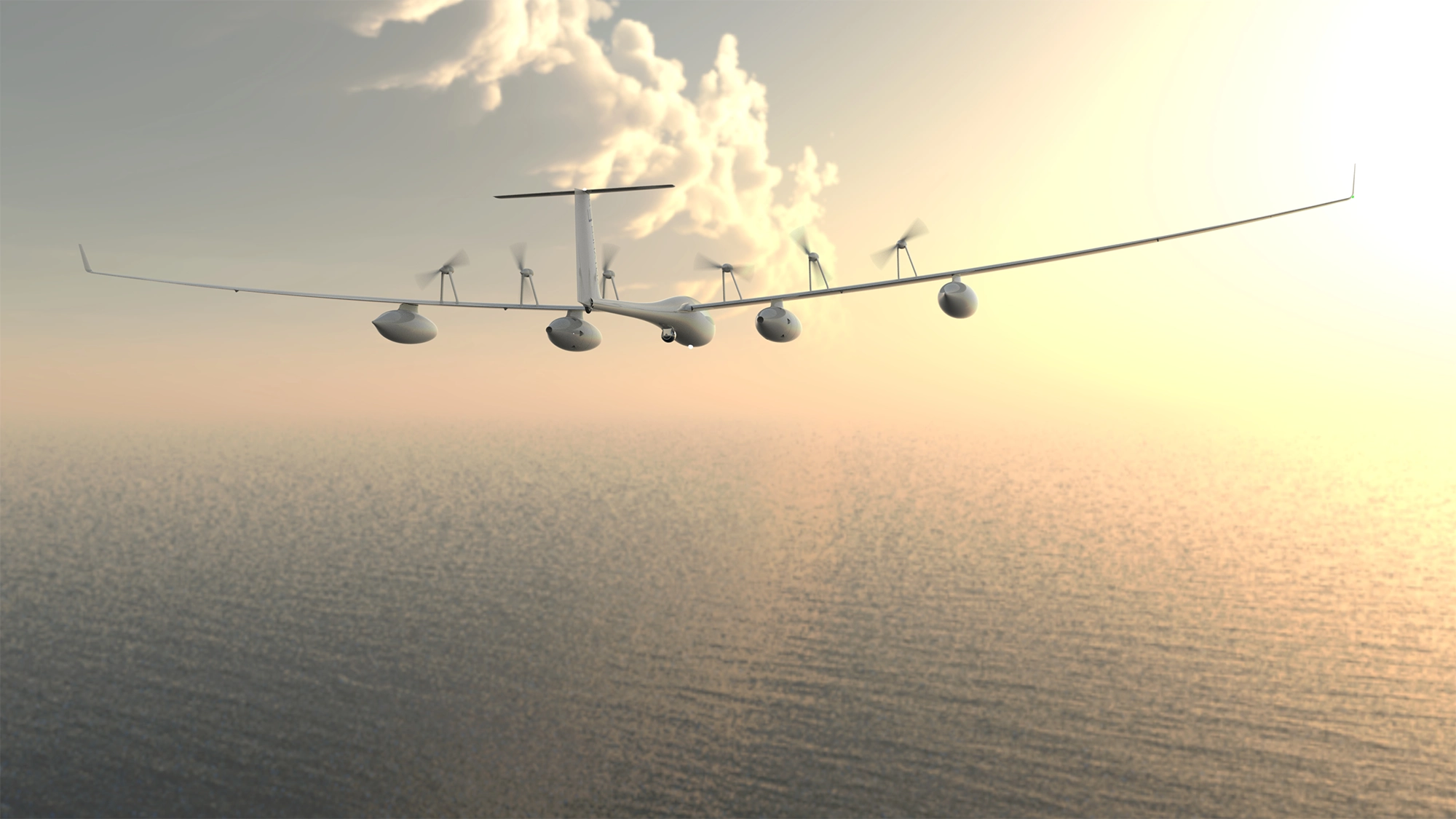

Book test missions in the Antares E2 6-motor research platform through us. Our “Flying Lab” takes your technology, e.g. sensors, manned or unmanned, into the air for up to 20 hours at a time. Our services include mission planning, preparation, execution and documentation.

This service will be available from 2023

Workshops

Are you or your team interested in exchanging views with our experts on specialist topics in aircraft development or on specific development and adaptation issues relating to our components?

Please inform us about your wishes via our contact page. We would be delighted to help you further.