Zero emission - in its purest form

The Antares® series of electric aircraft emphasize the pure delight of flying in harmony with nature. They are quiet, efficient and do not suffer from range limitations.

Thereby an Antares® aircraft always puts people at the center of an excellent flying experience: Our aircraft represent the art of engineering “Made in Germany”, they shine with well thought-out detailed solutions and are a valuable investment in quality of life and safety.

Independent, comfortable, agile and digitally highly connected

A cockpit that satisfies ergonomic standards, technology on a par with commercial aviation and a battery system that matches that of leading EV manufacturers. With the Antares® series, we have brought the world’s first fully electric self-launchers onto the market.

Having been copied more and more frequently in recent years, we remain the original. The most demanding pilots from all categories of aviation can be found among our worldwide customers – from pleasure pilots to record hunters. We want you to be uncompromisingly satisfied with our quality and innovative spirit, so that you too can take to the skies with performance, quietness, safety and lasting value – and be inspired by the power of nature!

Antares® Electric Performance Aircraft are EASA approved.

Flight characteristics

Antares® airplanes achieve the highest rankings and are designed for intuitive flying with stable and good-natured flying characteristics. The extreme maneuverability, enormous range and climbing capabilities as well as the relief of the pilot through complexity-reducing systems and digital integration ensure that every flight remains a pleasure even after many hours.

Electric drive

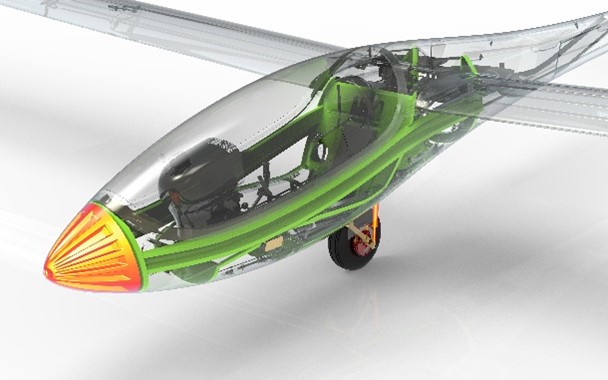

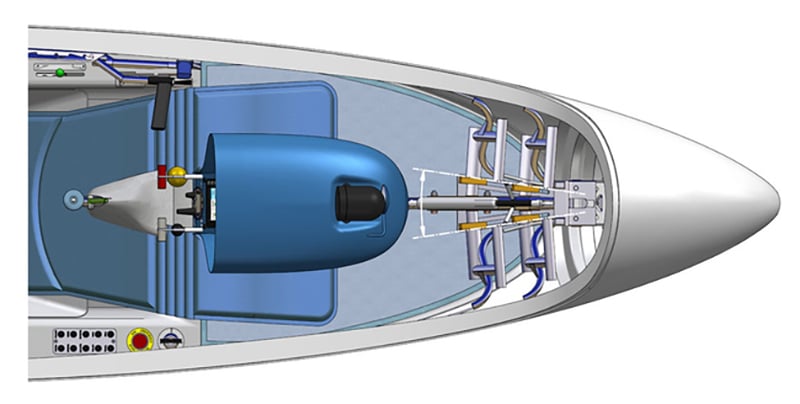

Our battery-powered propulsion system is the soul of Antares® electric aircraft. The engine, propeller, drive control and convenient single lever operation for extension/retraction and engine power setting are unique. No other electric platform can look back on so many flying hours. The drive system is designed for maximum efficiency, easily recognizable by the slow-turning 2-meter ( 6.6 ft ) propeller. The electric motor performs vibration-free, quietly and powerfully at any altitude. It can be retracted without pre-cooling immediately after use. The electric motor of the Antares brings a power of 42kW/57HP and thus achieves a climb rate of 4 m/s ( 790 ft/min ). During powered flight, the motor bay doors close hydraulically. The Antares® drive electronics and software are on a par with the world's best electric cars.

Battery system & charger

The Antares®.RED.3 battery system is the powerhouse of the Antares®. It supplies the aircraft with energy to achieve a climb altitude including self-launch of 5,600 meters ( 18370 ft ) and a range of up to 380 km ( 205 nm ) in the L version. The batteries are closely monitored. They are located in a fire-resistant and pressure-dissipating universal compartment within the wing structure. They are easily accessible for specialist personnel and can be (dis)assembled in a short time - but at the same time are kept at an optimum temperature and function reliably in all flight phases. In addition, the universal compartments can also accommodate future generations of batteries. The Antares.RED.3 charger is permanently installed in the aircraft. This means that the Antares® batteries can be supplied with power directly from all standard mains sockets without any extras, for example during soaring safaris.

Aerodynamics

The ideal aerodynamic basic design of the Antares® and many detail optimizations on the fuselage and wings appeal to pilots with high expectations.

One of our most important goals was to achieve perfect control harmony and response continuity. One of the many highlights of our development work is the implementation of new approaches, such as the hydraulically operated motor bay doors, which keep the fuselage completely closed while the electric motor is extended. The motor can be retracted without any pre cooling immediately after use.

State-of-the-art composite materials together with the latest in research and development knowledge deliver very high aspect ratios and low minimum wing loading. In addition, the electronically controlled water ballast system enables a wide range of wing loadings to adapt the aircraft to many weather situations. Our special materials and manufacturing processes at our Zweibrücken plant make it possible to practically implement the optimum wing.

Independence

On the ground, an Antares® operates as an unrestricted aircraft: capable of self-launching, with the help of the powerful and resilient electric motor and, thanks to the steerable tail wheel and wingtip wheels, it can taxi CO2-free and quietly to the point of take-off and lift off after a short take-off run. Every Antares® aircraft is also equipped with a combination tow- and winch-hook as standard. Antares® aircraft take off and land effortlessly on grass and asphalt. The large and hydraulically retractable 5-inch main landing gear with its powerful Beringer disk brake ensures comfort and safety even on difficult terrain. Like all modern sailplanes, an Antares® can be loaded and transported in a trailer. Our aircraft can be assembled and disassembled by one person in just a few steps and in less than 10 minutes - the one-man rigging aid, which was specially developed for this purpose and which has proven itself many times over, is included in the scope of delivery.

Comfort & ergonomics

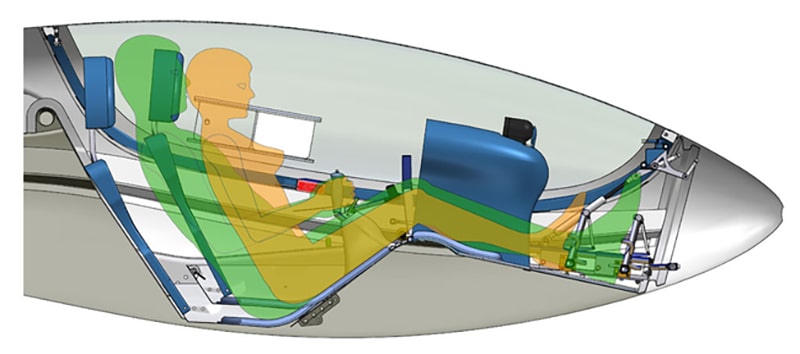

Good ergonomics result in performance advantages: On long flights, the scientifically optimized use of space in the Antares cockpit consistently prevents premature fatigue and loss of concentration. Incidentally, all pilots between 1.54 m ( 5′ ) and 1.94 m ( 6′ 4″ ) tall can comfortably be seated in our aircraft. The extra comfortable seating position offers excellent resting surfaces and comfort adjustments. Naturally, all controls are located where they are expected and within easy ergonomic reach. Aerodynamically optimal, low-noise ventilation brings the direct feel of air movement around the aircraft to the pilot inside and quickly provides clear visibility through the canopy. The particularly low-cut hood offers unrivaled visibility.

Extremely low maintenance effort

Choosing an Antares® always means investing in sustainability: The low maintenance requirements of our electric aircraft avoid downtime and save money. The first inspection, due after three years, can be performed by the owner or pilot. The first maintenance takes place only after 6 years.

Tailored to measure

A standard, Antares® electric aircraft already come equipped to a high level. Aditionally, it can be customized with a variety of individual options and tailored to the aesthetic and functional wishes of the owner. All the latest digital and analog options can be integrated into the cockpit of the Antares®. Each Antares® can be customized with more than 35 options in countless variants.

Already included in our comprehensive standard equipment: a large full-color display with checklists, audio annunciations, communication via cellular network, remote maintenance with high data security, failure logger, data logger for the entire life of the battery and much more. The instrument panel is available in three sizes and basic layouts, whereby all instrument panels are divided into segments with different inclinations so that the pilot always has a perpendicular view of his displays.

Factory fitted as standard:

Experience with your own eyes breathtaking scenery from a bird's perspective. This is the fascination in soaring. The Antares canopy was designed with this premise in mind. The exceptionally low-cut Plexiglas canopy is unrivaled and offers the pilot a unique all-round view.

The illustration shows the fuselage of the Antares and, as colored lines, the canopy cutouts of traditional designs in comparison.

The emergency canopy release is triggered by pulling the right hand canopy locking lever past the stop. Since there is no separate lever to operate, it is possible to fall back on muscle memory, which is important in an emergency.

A reduced visibility due to a misted-up canopy presents considerable dangers. The Antares can mitigate these situations. A sophisticated ventilation system brings fresh air through the canopy frame directly to the canopy and dissolves condensation within seconds. The picture shows the outlet apertures in the canopy frame for direct ventilation of the canopy.

The canopy gap is the Achilles heel of the airflow around the fuselage. High-precision manufacturing processes and the innovative use of materials ensure that the canopy frame fits extremely accurately while minimizing lengthwise expansion due to temperature differences.

The canopy of the Antares can be opened forwards and is supported by a gas spring. The robustly designed mechanism allows taxiing with the canopy open, which significantly contributes to comfort on warm days.

With know-how and experience from Formula 1 and based on research results from TÜV Rheinland, the cockpit of the Antares was designed as a survival space. The forward fuselage consists of two distinct sections: The nose of the aircraft is designed as a crumple zone. Here, considerable impact energy can be absorbed and dissipated by targeted deformation. To integrate this element, the fuselage was extended forward (about 10 cm / 4" compared to "traditional" fuselages) without sacrificing aerodynamics. The survival space behind has been reinforced with specially dimensioned stringers and bulkheads so that the cockpit can withstand high impact speeds and the crash energy can be transferred to the fuselage structure behind the person in the cockpit.

The high-quality microfiber fabrics are characterized by high UV resistance, dirt-repellent properties and effective moisture transport. The resistance to disinfectants and cleaning agents allows hygiene to be maintained in the cockpit.

The accommodation of 2 liter or 3 liter oxygen cylinders is prepared as standard.

Antares pilots like to talk about the pleasant feeling when their feet are warmed by the heat of the sun. The instrument console not only lets your legs bask in the sun, but also provides a breathtaking view from the unrivaled low-cut canopy. We will be happy to advise you on your instrumentation and offer three different console sizes to suit your requirements.

A passive headset is not for hearing protection, but for the best communication while taxiing and during takeoff. The microphone is attached separately to the headrest. The headphones are connected to the rear cockpit bulkhead via a high-quality XLR-5 connector.

In order to achieve a comfortable pressure point on the foot, the optimal position of the rudder pedals is not only determined by the longditudal distance, but also by the width and height of the pedal position. A specially developed mechanism therefore also adjusts the pedals of the Antares in width and height along with the longditudal setting. This ensures that for small pilots the pedals do not disappear behind the instrument console, but are automatically adjusted to a wider and lower setting. Of course, the pedal adjustment can also be used in flight.

In order to achieve a comfortable pressure point on the foot, the optimal position of the rudder pedals is not only determined by the longditudal distance, but also by the width and height of the pedal position. A specially developed mechanism therefore also adjusts the pedals of the Antares in width and height along with the longditudal setting. This ensures that for small pilots the pedals do not disappear behind the instrument console, but are automatically adjusted to a wider and lower setting. Of course, the pedal adjustment can also be used in flight.

A highly dynamic aircraft like the Antares requires a perfectly compensated pneumatic system. This was achieved by carefully tuning the probes and decoupling the altimeter and airspeed indicator from the pneumatic system for the variometers.

If the TE compensated multi-probe is not mounted before takeoff, the altimeter and airspeed indicator are not affected in their function.

To avoid disturbing the airflow around the fuselage, the radio antenna is installed inside the vertical stabilizer.

High wing loading; - Stable flight characteristics - Safe ballast management

Due to very good-natured flight characteristics and the carefully harmonized controls, the Antares allows safe yet agile thermaling even at high wing loading and low speed. However, if ballast needs to be released, the high-strength spars allow the outer tanks to be drained first. This gives the Antares additional agility when partially loaded. The amount of water in the trim tank within the vertical stabilizer is automatically adjusted by the control and regulation system so that partial loads do not result in a shift in the centre of gravity. The control of the valves is fully electrical and much more reliable compared to mechanical solutions.

Water ballast:

21E = 126 liters (33.3 US gal.)

23E = 247 liters (65.3 US gal)

During the development of the Antares landing gear, the focus was on two development goals. The landing gear design should offer maximum comfort when taxiing and at the same time be able to absorb a high amount of energy in the event of a crash. The two gas springs with their large suspension travel and the high extending 5" wheel provide precisely these characteristics. They protect pilot in the event of a crash and effectively absorb unevenness of the runway.

As standard, the Antares is equipped with a high-quality Beringer wheel and hydraulically actuated disc brake with brake force limiter. This enables powerful yet controlled braking on all runway surfaces. The braking force is controlled via the airbrake lever.

The landing gear is retracted and extended hydraulically by manipulating the landing gear switch in the cockpit. Unintentional retraction on the ground is safeguarded by ground/air detection.

The Antares is equipped with a combination hook that can be used for both aerotowing and winch launching.

A special highlight is the horizontal stabilizer, which can be mounted easily and safely without the use of any tools. Of course, the other control surfaces are also connected automatically.

The Antares' triple panel cascading airbrakes produce very high drag with little loss of lift and allow for very steep approaches. The stall speed increases only minimally and thus facilitates low touchdown speeds.

The robust, steerable star wheel makes it easy to taxi to the intended position without the need for external assistance. The very sensitive power control in the lower speed ranges of the drive system makes child's play out of precise maneuvering on the ground. Taxiing requires only a minimum amount of battery power, which is always available even after intensive use of the drive during flight. The lowered wing rolls on the wing tip wheels and, together with the easily accessible rudder pedals, this also enables convenient manual maneuvering in the takeoff grid, when aligning in front of the hanger or parking on the apron. With your Antares you enjoy this high level of comfort and autonomy.

Technical sophistication can even be found in the tail dolly. The mounted tail dolly is automatically detected by the Antares main computer and this generates a caution message at the appropriate item in the pre launch checklist.

Technical sophistication can even be found in the tail dolly. The mounted tail dolly is automatically detected by the Antares main computer and this generates a caution message at the appropriate item in the pre launch checklist.

The 42 kW EM42 brushless external rotor motor is virtually maintenance-free and enables high climb rates of up to 4 m/s ( 790 ft/min ). Due to inherent system characteristics, the drive offers a high level of operational reliability and runs vibration-free. This avoids problems relating to vibration and fatigue.

Not only its agility and dynamic performance, but also the incredible amount of energy stored in its wings make the Antares a truehigh-energy aircraft.

The battery system is available in two variants: S-tandard and L-arge. The S variant has energy for a climb altitude (including self-launch) of 4,200 meters (13780 ft), the L variant for 5,600 meters (18370 ft) available in the wings. This corresponds to a range of 280 km (50 nm) or 380 km (205 nm). These fantastic values are the result of 25 years of experience and outstanding engineering work.

Charging takes no longer than 9 hours at a 220V socket and is also possible in a disassembled state inside the trailer with the optionally available accessories. If work on the battery system is necessary, the battery can be pulled out through the root rib without damaging the wing.

The Electric Drive Control System (EDCS) controls and monitors the Antares' electric drive, battery system, hydraulics and water ballast. All information is displayed clearly and legibly on the large 4.3 inch full color display. Caution and warning messages appear in understandable plain text.

In addition, the caution and warning messages are immediately communicated as a voice announcement. This concept is common practice in commercial aviation and contributes significantly to the quality of safety in the Antares, as it allows the pilot to focus fully on flying. The audio announciation is available in different languages.

Another safety element is the well thought-out selection of the information shown on the EDCS display. It changes automatically depending on the situation and always shows exactly what is important for the pilot: before takeoff the pre-flight checklist, in flight the gliding or powered flight display and finally, after the flight, the flight log information is available. In addition, the system maintains a ffailure log, which helps to make maintenance even more efficient and safe.

The entire propulsion system is controlled through a single lever on the left-hand cockpit wall. Due to its shape and position alone, the lever is as easy and intuitive to find and operate - not unlike the way pilots are used to operating the flaps controls, for example.. This allows the flying person's view and attention to remain outside the cockpit. Functionalities such as retracting and extending the motor and braking and aligning the propeller are executed automatically.

Landed on an unfamiliar airfield but there is no charger available? Not with the Antares. Due to the integrated charger, it is possible to recharge at any mains outlet. A real convenience if the dream of a soaring safari is to become reality.

No compromise when it comes to quality. The high-quality Klixon circuit breakers are within easy reach inside the cockpit.

The 2-meter ( 6.6 ft ) propeller is specially tailored to the motor and requires a correspondingly large motor bay, which is only opened briefly for the 8-second retraction and extension phases of the motor. This enhances the high efficiency of the propeller during powered flight. The motor bay doors open and close automatically.

The Antares can be rigged single-handedly, as the specially developed rigging aid, which is optimized for the weight of the wings, considerably reduces the effort required. The rigging time is approx. 10 minutes.

The seat pan can be adjusted both longitudinally and vertically, and the backrest is in-flight adjustable. height adjustable headrest

The adjustable seating system of the Antares allows for people of all sizes to find a consistently comfortable seating position. This comfort counteracts fatigue and therefore contributes significantly to the pilot's long-term performance. The seat pan can be unlocked and adjusted in only a few simple steps. The backrest as well as the headrest are in flight adjustable.

Seat and backrest smallest setting.

Seat and backrest in the largest setting.

In flight adjustable backrest.

Optional features:

Human stature does not usually conform to a standard, and this is why it is important to have the ability to customize the ergonomics of the cockpit. Many pilots have their own preferences for equipment and instrumentation or want to add a personal touch to the design of their aircraft. This means that individualization is indispensable in ensuring a perfect flying experience. The Antares can be configured precisely to your requirements, from the optimum center of gravity to the interior, instrumentation and position of the control stick. We would be delighted to support your Antares experience with in-depth consultation. Explore your options – the possibilities for customization go beyond the options shown below:

Choose your Antares Electric Performance Aircraft

Teases out the maximum. And the clouds from below.

The Antares® 21E offers the ultimate sustainable flying experience. Convincing – with a wingspan of 21.5 meters and easy handling on the ground and in the air – as agile as a 15-meter aircraft.

Technical data (selection):

The optimum between the extremes.

The Antares® 23E pushes the boundaries for open class pilots – with its optimal aspect ratio and a wingspan of 23 meters, it flies with the agility of an 18-meter aircraft.

Technical data (selection):

If you would like to receive a quotation or simply ask a question, use our contact page to get in touch with us

More info about the Antares series:

Training & after-sales

All Antares owners receive a 4-hour in-depth briefing when they take delivery of their aircraft. We also offer maintenance, upgrade and update services.

Made in Germany

Designed, developed and produced in the German tradition for technical excellence. Take a look behind the scenes and discover our company history.

Partners & Awards

We are delighted to have been awarded important prizes for our engineering achievements. Here you will find an overview of prizes and awards as well as our partners.

Product archive

You have not found what you were looking for? Take a look at our product archive with previous aircraft types